Corporate

Americas

United States & Canada

México

America Latina

Brasil

Oceania

Australia

New Zealand

Europe

Asia

India

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

日本

中国

대한민국

台湾

Other Countries

Efficient workflow and labor savings

Ensuring the safety and security of staff and products

Reduction of overtime costs

Challenges

A significant amount of time is spent on inventory checks and counting when receiving and shipping goods

There are security concerns regarding goods being carried in and out of cases

Numerous customer inquiries arise due to the inability to check the status of repairs and processing

Overtime work is required to perform inventory checks after business hours

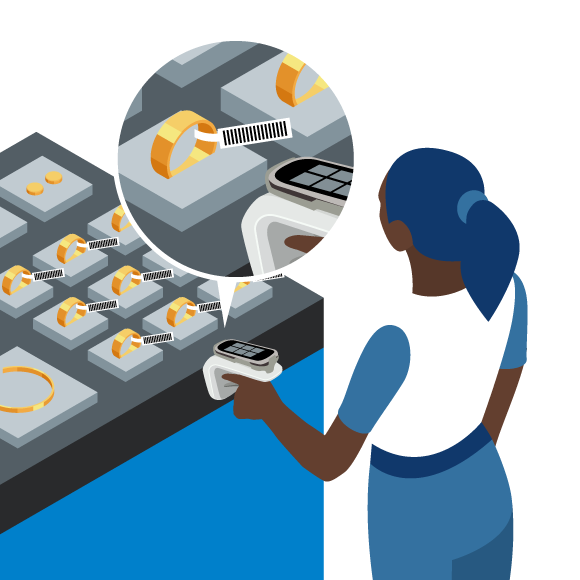

RFID-based management of jewelry and accessories

Benefits

Improved efficiency and accuracy of inventory management

RFID batch reading technology makes inventory operations faster and more accurate.

- Scan products from outside the showcase without touching them.

- Up to 90% reduction of conventional work time (e.g., 2 persons x 3 hours → 1 person x 30 minutes)

- Inventory can be updated in real time, further improving management accuracy

Ensuring the safety of staff and products

Eliminates the need for inventory checks after closing and enhances security for staff and jewelry.

- Smooth inventory during business hours

- Minimize risks associated with carrying valuables

- Reduces the risk of theft or loss and ensures safe store operations

Reduction of overtime costs

Overtime work for inventory can be reduced, and labor costs and overtime expenses can be reduced by shortening work hours.

- Eliminates the need for inventory checks after business hours and reduces workload

- Staff time can be used for higher value-added tasks, reducing labor costs and overtime

<Use Case 1> Enhancing inventory control during events with frequent product movement

Optimize inventory management at events and exhibitions.

- Batch reading streamlines operations and increases the number of inventories taken during the event

- Maintains accurate inventory control even in a highly mobile environment

<Use Case 2> Enhanced processing and process control

Visualize the progress of processing and repairs to achieve a smooth workflow.

- Obtain product information without spending man-hours on each process

- We can introduce a system that updates information in real time and allows customers to check the status themselves

Related Solutions

SATO support starts here

Need specifics on products or pricing?

Connect with our technical experts for fast, reliable support.