Corporate

Americas

United States & Canada

México

America Latina

Brasil

Oceania

Australia

New Zealand

Europe

Asia

India

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

日本

中国

대한민국

台湾

Other Countries

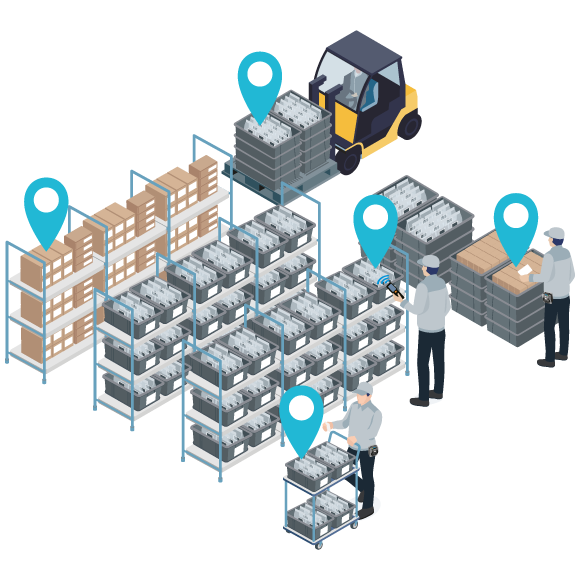

Improve location management

Boost work efficiency and prevent errors

Show real-time inventory status

Challenges

Location management of raw materials is complicated and time consuming to locate

Shortage of manpower, dependence on skilled workers, and inconsistency in work

Location management of raw materials using positioning technology

Benefits

Reduces time spent searching for raw materials

Time spent searching for raw materials is reduced and the workload of operators is lessened.

Improve inventory control accuracy

Real-time inventory status and proper inventory management improves accuracy.

Related Solutions

SATO support starts here

Need specifics on products or pricing?

Connect with our technical experts for fast, reliable support.