Corporate

Americas

United States & Canada

México

America Latina

Brasil

Oceania

Australia

New Zealand

Europe

Asia

India

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

日本

中国

대한민국

台湾

Other Countries

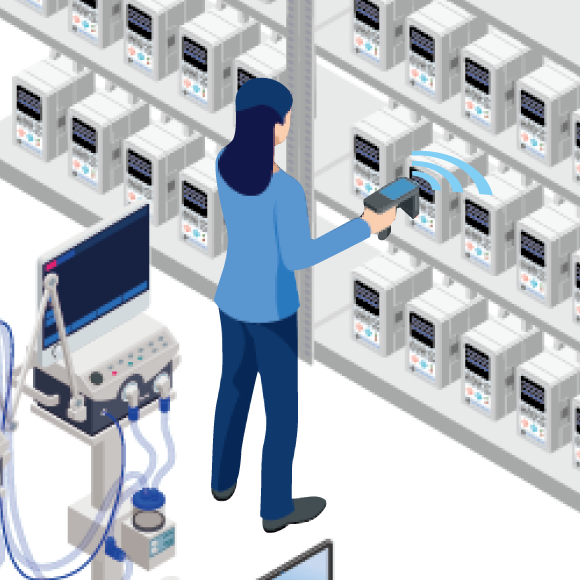

Reduced work time

Reliable inventory control

Challenges

Medical device inspection and inventory checks are time-consuming

Recording usage histories for medical devices requires significant time and effort

Barcode-based inventory checks can lead to missed scans or double scans

Devices stored on high shelves are difficult to access, making barcode scanning cumbersome

Medical Device Management with RFID

Benefits

Real-time Visualization and Automatic Usage History Recording

Managing each medical device individually with RFID labels provides the quantity, location, and usage status of devices in real time.

Staff members simply scan the device with a terminal when using it. The system automatically records the usage history, accurately tracking who used which device and when.

This eliminates the burden of inventory checks and stock verification, enabling reliable and transparent asset management.

Related Solutions

SATO support starts here

Need specifics on products or pricing?

Connect with our technical experts for fast, reliable support.