Corporate

Americas

United States & Canada

México

America Latina

Brasil

Oceania

Australia

New Zealand

Europe

Asia

India

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

日本

中国

대한민국

台湾

Other Countries

PJM RIFD

Enhanced operational accuracy

Improved operational efficiency

Challenges

The process of accurately identifying, receiving, and shipping multiple blood donation bags is labor-intensive and time-consuming

There are concerns about the accuracy of traceability and inventory management

A significant amount of time is spent on picking and delivery operations

There is a growing burden in meeting compliance requirements

Improving Traceability Efficiency with PJM RFID

Benefits

What is PJM RFID?

PJM (Phase Jitter Modulation) RFID is a high-speed, high-precision RFID technology compliant with ISO 18000-3 Mode 2.

- Up to 600 tags read per second

- Stable reading performance even in metallic, water, and stacked conditions

- Scanning is possible without worrying about tag orientation (3D reading)

- Label material for radiation sterilization

- Operates in cryogenic conditions:

- C-chip series: down to –40°C

- D-chip series: down to –80°C

- NFC-enabled and readable with smartphones

- Supports ISBT 128-compliant data recording

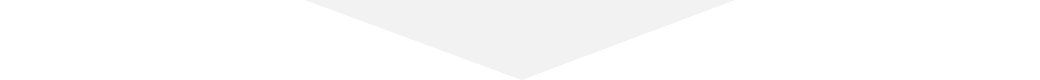

Accurate and efficient receiving and outbound processing

Using a PJM RFID tunnel reader, blood donation bags inside the container can be batch-scanned.

The system accurately reads labels regardless of their orientation or spacing, significantly reducing receiving time.

Temperature loggers automatically record temperatures during transport, ensuring safety and compliance.

Accurate identification of blood components for traceability

After blood products are prepared, a dedicated PJM RFID label is issued and applied.

By securely linking each blood product to its original donor bag, a clear history is maintained, ensuring full support for recall procedures and quality assurance.

Real-time visibility of all inventory and all inventory movements

PJM RFID–enabled refrigerators, freezers, and open shelves automatically capture inventory information each time the door is opened or closed.

Quantities, storage locations, expiration dates, and removal times can be monitored in real time.

Furthermore, when an error occurs, an automatic alert is sent to notify the staff.

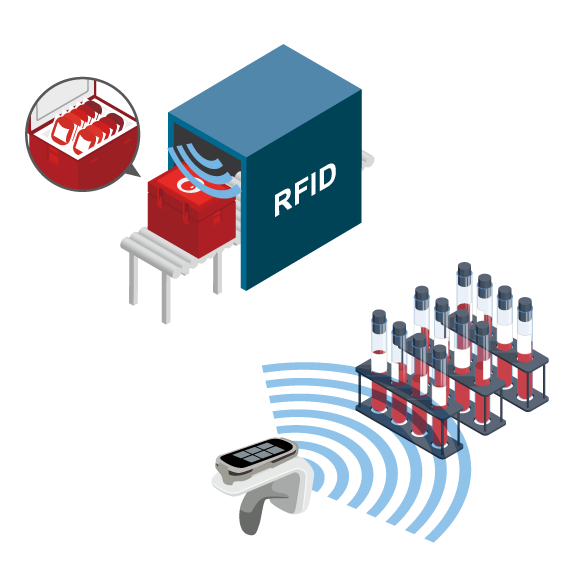

Quick and accurate order picking

For orders from medical institutions, picking can be performed through batch scanning.

The verification process becomes faster, minimizing the amount of time the products are exposed to outside temperatures.

Accurate and efficient delivery

With a PJM RFID tunnel reader, entire transport containers can be scanned at once.

It identifies the contents regardless of label orientation, achieving both labor savings and high accuracy in loading and unloading operations.

In addition, temperature loggers inside the container record temperatures during transport, ensuring robust quality control.

Related Solutions

SATO support starts here

Need specifics on products or pricing?

Connect with our technical experts for fast, reliable support.