Corporate

Americas

United States & Canada

México

America Latina

Brasil

Oceania

Australia

New Zealand

Europe

Asia

India

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

日本

中国

대한민국

台湾

Other Countries

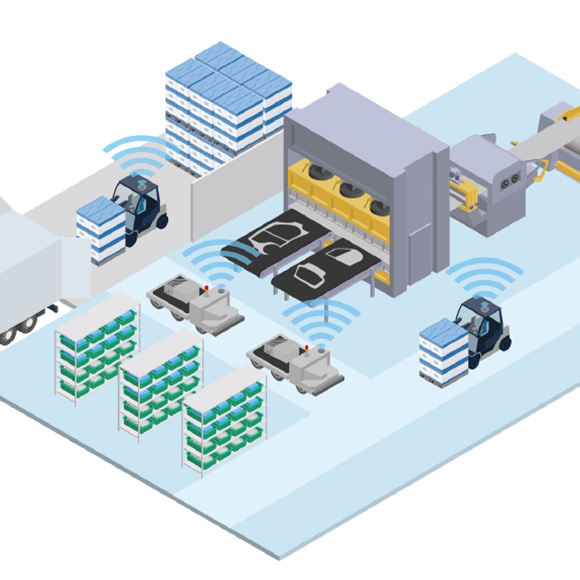

Real-time tracking of transport vehicle location

Capable of monitoring and analyzing delays and other situations

Achieving optimal placement

Challenges

Unable to locate transport vehicle

The cause of congestion and work waiting for transport vehicles has not been identified

Determining the right number of transport vehicles to meet demand without over- or under-allocating resources

Visualizing Vehicle Flow Lines with Positioning Technology

Benefits

Real-time acquisition of transport vehicle position

You can capture real-time location and traffic flow data with high precision—accurate to within just 50 cm.

Optimal placement of transport vehicles

Using this data, you can allocate transport vehicles in the most efficient configuration. By identifying events such as retention, delays, and bottlenecks, teams can analyze workflows over time and drive continuous operational improvement.

Camera-based full inspection is added to further eliminate display confirmation errors

The GHS label automatic application system integrates label printing, application, and image inspection into one streamlined workflow. What once required manual visual checks with S-ROBO is now as simple as placing the product on the conveyor. By removing manual labeling, barcode scanning, and other repetitive tasks, it delivers significant labor savings and lifts overall productivity.

Related Solutions

SATO support starts here

Need specifics on products or pricing?

Connect with our technical experts for fast, reliable support.