Corporate

Americas

United States & Canada

México

America Latina

Brasil

Oceania

Australia

New Zealand

Europe

Asia

India

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

日本

中国

대한민국

台湾

Other Countries

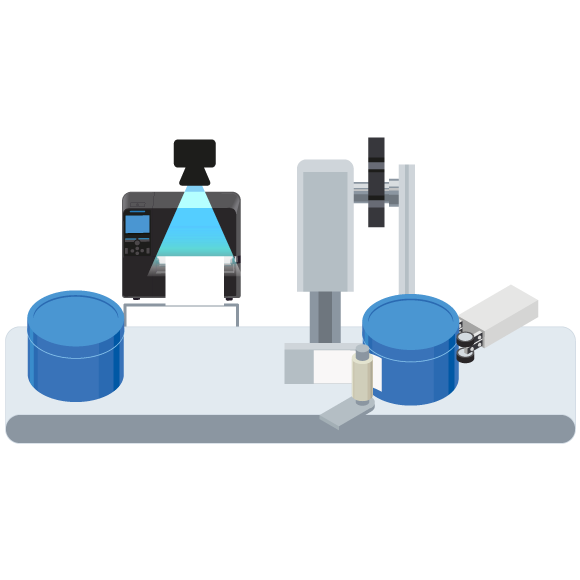

Reduces labor and increases efficiency

Customize auto-label placement

Tailor automated systems to specific needs

Challenges

Time-consuming work to apply labels to curved surfaces, cylinders, and exterior surfaces

Difficult to secure workers during peak season

Labeling errors

Automated systems have a high upfront cost

Automated operations with robotic labeling and printing systems

Benefits

Enables attachments to a variety of shapes

The attachment method and placement can be customized to match the exact requirements of the target object.

Automated cameras and robotic arms ensure precise, hassle-free label application

Labor savings is realized by eliminating manual labeling, barcode scanning, and other tasks, thereby improving overall productivity.

Related Solutions

SATO support starts here

Need specifics on products or pricing?

Connect with our technical experts for fast, reliable support.