Corporate

Americas

United States & Canada

México

America Latina

Brasil

Oceania

Australia

New Zealand

Europe

Asia

India

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

日本

中国

대한민국

台湾

Other Countries

Automatic capture of work by process

Visualize, analyze, and improve data

Challenges

Not knowing who, when, where, or how much work is being done in the plant

Work data needs to be captured, but the burden on the operator needs to be as little as possible

Lack of reliability in captured data

Work records and error prevention through location technology

Benefits

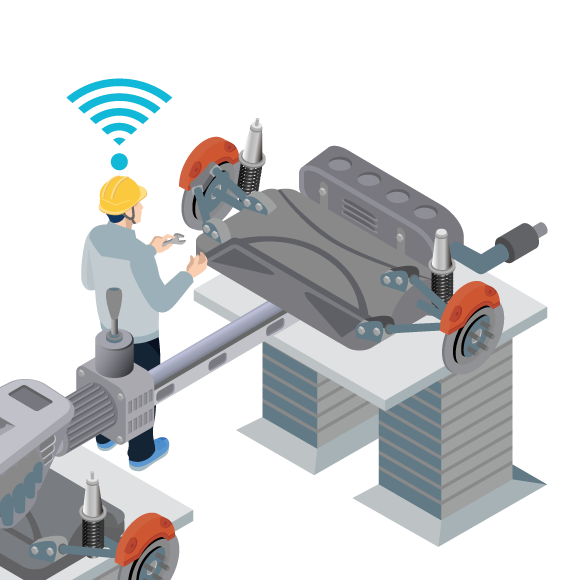

Using location and positioning technology to capture work activity

By linking with data output from tools such as torque wrenches, it is possible to record work information such as who tightened the screws, which body, and with what amount of force.

Visualization of work history

By visualizing and analyzing work histories, it is possible to improve the work site, review manufacturing costs, and optimize manpower planning.

Related Solutions

SATO support starts here

Need specifics on products or pricing?

Connect with our technical experts for fast, reliable support.