The customer, a leading player in the apparel manufacturing sector, grappled with persistent mis-packaging issues, posing a significant operational challenge. Despite intensive training efforts and revised guidelines, mispackaging problems persisted, negatively impacting operational efficiency and resulting in financial impact amounting to $40,000 USD across the network of factories. The financial consequences were primarily due to penalty claims resulting from mispackaging against brand owner orders.

Financial Strains to Operational Gains: How SATO’s RFID Solution Rescues Apparel Manufacturer

Business Challenge

Solution

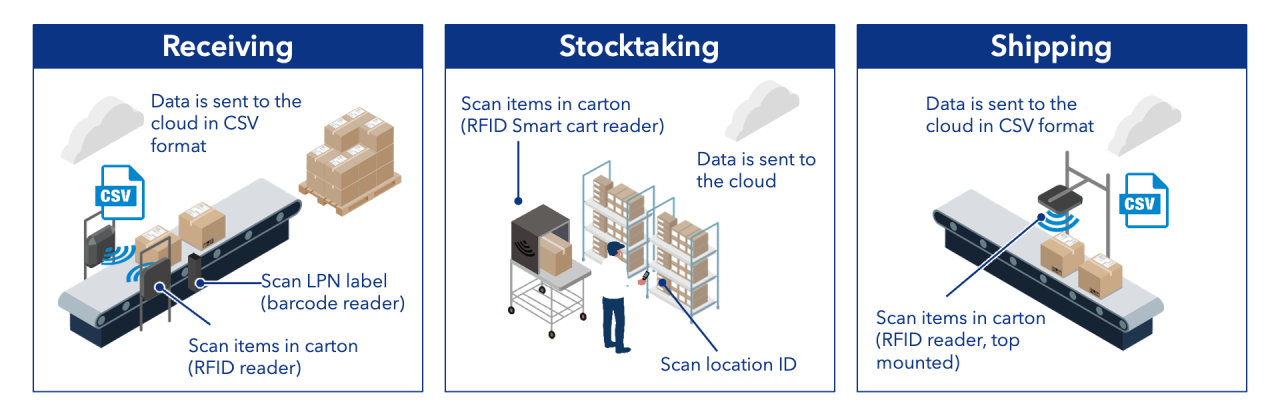

SATO proposed a comprehensive data integration solution using RFID to address inefficiencies in the shipping process. This solution involved the development of customized software, namely the RFID shipping verification system, and the integration of an RFID tunnel scanning solution within their factory’s IT infrastructure.

Before the implementation of this solution, the shipping process relied on manual counting of each item, followed by packing into boxes for shipment. However, this manual approach posed a significant risk of errors, including miscalculations and mispackaging, due to human factors.

With SATO's solution, individual items were equipped with RFID tags before being placed into boxes for shipment. The RFID tunnel scanning solution was then deployed to verify the accuracy of all items automatically. This automated verification process significantly reduced the time required for shipping by 90 percent.

Overall, SATO's RFID integration solution not only streamlined the shipping process but also mitigated the risk of mispackaging associated with manual counts, ensuring greater accuracy and efficiency in the fulfillment of orders.

Results

- Annual penalty from mispackaging costs went from $40,000 USD to zero

- Saved scanning time by 90 percent

- Streamlined operations