Heavy industry is a significant source of global CO2 emissions and remains on a general upward trend, despite industries' efforts to achieve net-zero targets. In manufacturing, emissions are projected to increase by 17 percent between 2024 and 20502. The SATO Group is working to reduce the environmental impact in the manufacturing and shipping of its products, and this is part of those efforts.

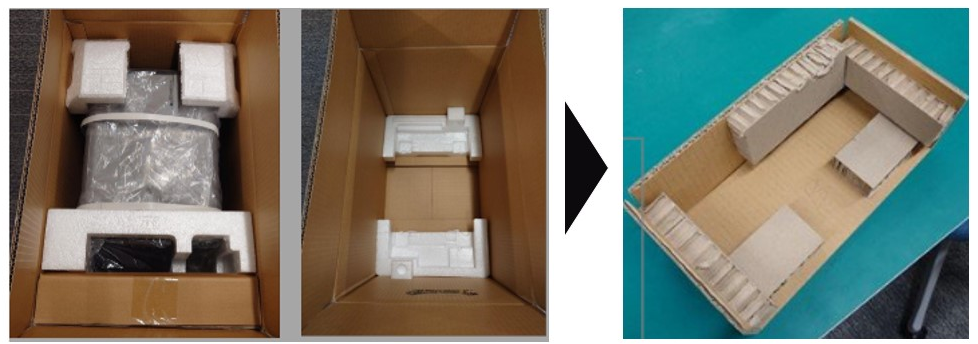

The new cushioning structure features a honeycomb board attached to the cardboard frame, providing superior strength and shock resistance to secure the printer. We have conducted rigorous quality assurance testing on the reliability of the new materials through drop tests, vibration tests, and compression tests, which demonstrate that the new paper-based cushioning enables equally stable and secure packaging of printers, comparable to petroleum-based materials.

SATO estimates that the new material will deliver a 39 percent savings of CO2 emissions per unit3. Based on fiscal year 2023 sales, it also expects to reduce approximately 8,596 kg of plastic waste annually. As previously announced, the CL4NX Plus printers are now produced with recycled casing, which contributes to CO2 emissions reductions while having no negative effect on product durability.